Introduction to Eton Automation's Products: SMT Buffer Unit

Published Time:

2025-10-02

Eton specializes in the SMT industry, including pick and place machine, reflow ovens, conveyors, and PCB buffers, designed to optimize production lines, reduce downtime, and increase efficiency in industries such as electronics, automotive, and medical manufacturing.

As the manufacturing industry continues to evolve with the demands of faster production times and higher precision, automation has become a key factor in optimizing production lines. Eton Automation, a leading manufacturer of automated equipment, offers an array of high-quality products designed to improve production efficiency. Among these products, the SMT Buffer Unit stands out as an essential component in the Surface Mount Technology (SMT) production line. This article will delve into the details of the SMT buffer unit, highlighting its importance in the SMT production process, its working principle, its components, and the value it brings to modern manufacturing.

What is an SMT Buffer Unit?

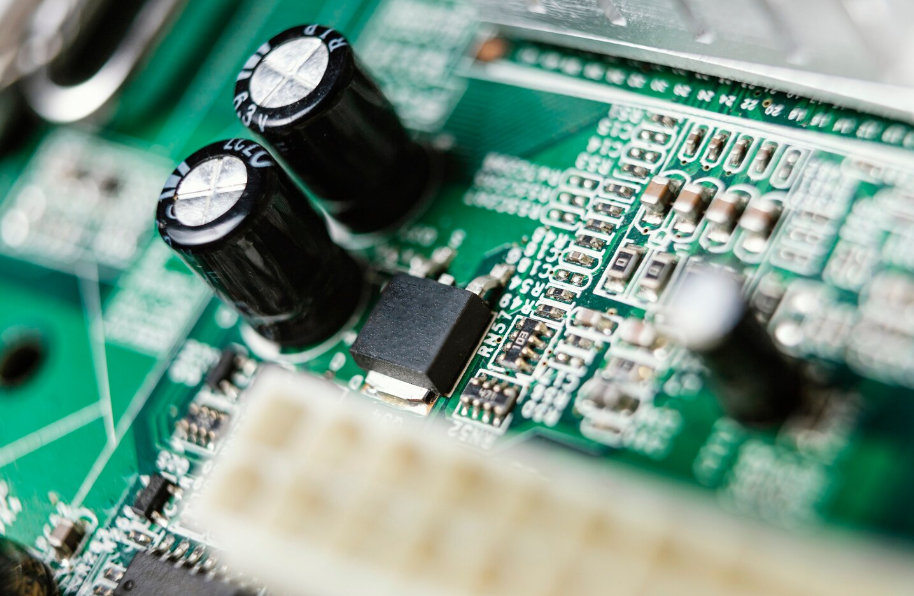

The SMT Buffer Unit is a crucial piece of equipment used in SMT production lines. It plays the role of managing the flow of printed circuit boards (PCBs) between different stages of the production process, ensuring that there are no bottlenecks or delays due to variations in the speeds of different machines. A buffer unit allows for the temporary storage of materials, providing a smooth transition between different production stations. This is especially important when production processes operate at different speeds, such as in the case of PCB assembly, soldering, or inspection.

What Is SMT Buffer Conveyor?

The SMT Buffer Conveyor is a key part of the SMT buffer unit. It is a system of conveyors designed to temporarily hold and transport PCBs through various stages of the SMT production process. These conveyors are integrated with the buffer unit, allowing for the efficient transfer of materials while minimizing delays and optimizing the flow of production. The buffer conveyor ensures that materials are not waiting idle in any part of the production line, which helps to maintain the speed and efficiency of the entire process.

What Is SMT PCB Buffer?

The SMT PCB Buffer refers to the storage section within the SMT buffer unit that temporarily holds PCBs between different production stages. The buffer helps prevent the overloading of specific stations by allowing PCB boards to wait until the next station is ready to handle them. This helps maintain a constant flow of materials through the production line, which ultimately improves the overall efficiency of the SMT process. The SMT PCB buffer is highly customizable and can be adjusted according to the production requirements, such as different sizes and types of PCBs, as well as production speeds.

How Does an SMT Buffer Unit Work?

The primary function of an SMT buffer unit is to manage the flow of materials in a production line, ensuring that the entire process runs smoothly without interruptions or delays. Here’s how it works:

1. Buffering Materials: The SMT buffer unit is equipped with a series of conveyors that temporarily hold materials between workstations. When one station is processing materials faster than another, the buffer unit stores the excess material and releases it at the appropriate time. This helps prevent backups and production stoppages.

2. Conveyor Integration: The buffer unit’s conveyors are integrated into the SMT production line. They are designed to move materials in and out of the buffer section, ensuring that materials are stored for just the right amount of time before continuing to the next stage of the process.

3. Real-Time Monitoring and Control: The buffer unit comes with an advanced control system that monitors the status of the production line in real-time. Sensors detect the flow of materials, and the system adjusts the speed and operation of the conveyors accordingly. This ensures that materials are always available where they are needed, reducing the risk of delays or excess accumulation of materials.

4. Optimized Storage Capacity: The buffer unit is designed with adjustable storage capabilities, meaning that it can hold a set number of PCBs based on the production requirements. Depending on the complexity and speed of the production line, the buffer can be expanded or reduced in size to meet specific needs.

Key Features of SMT Buffer Unit

Eton Automation’s SMT Buffer Units are designed with several important features that make them stand out in the market. Here are some key features:

1. Increased Production Efficiency

By effectively managing the flow of materials between production stations, the SMT buffer conveyor ensures that the entire production line runs smoothly without unnecessary delays. This results in increased overall production efficiency and throughput, which is critical in meeting the growing demands of the market.

2. Flexible Storage Capacity

The SMT PCB buffer is highly flexible and can be customized to handle different types of PCBs and materials. The buffer’s storage capacity can be adjusted to accommodate specific production requirements, whether for high-volume production or smaller batches.

3. Reduced Downtime

The buffer unit helps minimize downtime by ensuring that materials are always available for the next stage of production. This reduces the likelihood of production stoppages due to waiting for materials or misalignment between workstations. It also minimizes the need for manual intervention, further reducing human error.

4. Improved Product Quality

With the ability to efficiently manage materials, the SMT buffer unit contributes to maintaining the overall quality of the production process. By eliminating delays and interruptions, it ensures that each PCB moves through the production line with minimal defects, leading to higher-quality final products.

5. Advanced Control System

Eton Automation’s SMT buffer units are equipped with advanced control systems that provide real-time monitoring of the production line. These systems help identify any issues before they become problems, allowing operators to make adjustments proactively. The control systems can also adjust the speed and operation of the conveyors based on real-time data, ensuring optimal production efficiency.

Applications of SMT Buffer Unit

The SMT buffer unit plays a critical role in several industries where precision and efficiency are essential. Below are some of the key industries that benefit from the use of SMT buffer units:

1. Consumer Electronics Manufacturing

In the consumer electronics sector, where products like smartphones, tablets, and laptops are produced in large volumes, SMT technology is used extensively. The SMT buffer unit ensures that the production lines are efficient and can handle the high-speed, high-volume demands of consumer electronics manufacturing.

2. Automotive Electronics

With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the automotive industry increasingly relies on electronic components. The **SMT buffer conveyor** helps automotive manufacturers maintain the speed and precision needed in the production of PCBs for automotive electronics, ensuring that the production process is optimized and efficient.

3. Industrial Electronics

Industrial electronics, including automation equipment, control systems, and robotics, also rely heavily on SMT technology. The **SMT PCB buffer** ensures that the production process for these critical components remains smooth and uninterrupted, even when there are variations in production speeds between different workstations.

4. Medical Device Manufacturing

In the medical device sector, precision and reliability are paramount. The SMT buffer unit ensures that the production of electronic components for medical devices, such as diagnostic machines and monitoring equipment, is efficient and consistent. The unit helps meet stringent regulatory requirements while also reducing production errors and downtime.

Why Choose Eton Automation’s SMT Buffer Unit?

Eton Automation’s **SMT buffer unit** offers a range of advantages that make it an ideal choice for companies looking to optimize their production lines. Here’s why you should choose Eton Automation:

1. High Customizability

Eton Automation offers highly customizable buffer units that can be tailored to fit the specific needs of your production line. Whether you need a buffer unit for high-volume production or a more specialized solution for a unique product, Eton can provide the right equipment for your needs.

2. Advanced Technology

Eton’s SMT buffer units feature cutting-edge control systems and automation technologies. The advanced sensors and real-time monitoring ensure that your production line operates at maximum efficiency, reducing the risk of downtime and delays.

3. Durability and Reliability

Eton Automation’s buffer units are built to last. Designed with high-quality materials and robust engineering, these units provide long-term reliability and durability, even in the most demanding production environments.

4. Comprehensive Support

Eton Automation provides exceptional customer support, from initial consultation to post-sale service. Their team of experts ensures that your buffer units are properly installed, calibrated, and maintained, ensuring smooth operation throughout their lifespan.

5. Competitive Pricing

Eton Automation offers competitive pricing without compromising on quality. Their SMT buffer units provide excellent value for money, offering an efficient and cost-effective solution for manufacturers.

Conclusion

In the world of automated manufacturing, SMT buffer units have become essential for optimizing production efficiency and ensuring smooth operation in SMT production lines. Eton Automation’s SMT buffer conveyors, SMT PCB buffers, and SMT buffer units provide the necessary support to keep production lines running smoothly, helping manufacturers maintain high levels of efficiency, reduce downtime, and produce high-quality products.

If you are looking for a reliable, customizable, and efficient solution for your production line, Eton Automation's SMT buffer unit is the ideal choice. With its advanced technology, durable construction, and excellent customer support, Eton Automation is ready to help your business succeed in today’s competitive market.