Automatic Optical Inspection (AOI): The Indispensable "Quality Gatekeeper" on SMT Production Lines

Published Time:

2025-10-13

Automated Optical Inspection (AOI) uses advanced cameras and AI to automatically detect PCB defects in SMT lines. Inline and Pre-reflow AOI enable real-time monitoring and early fault prevention, enhancing quality and cutting costs.

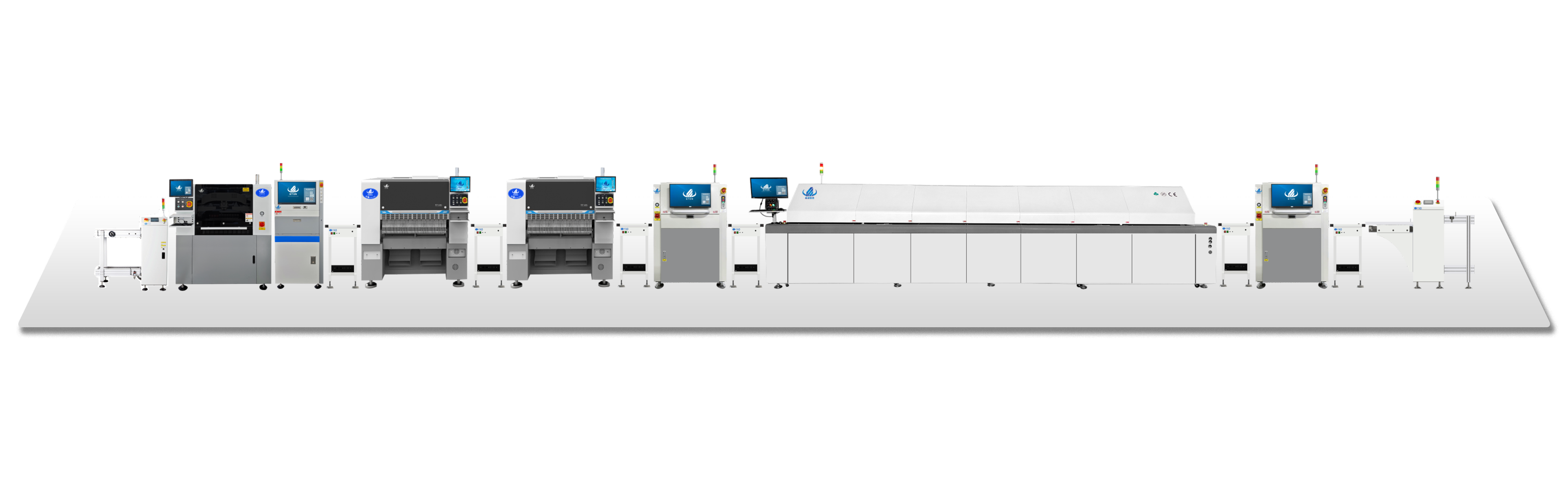

In the electronics manufacturing industry, especially in surface mount technology (SMT) production lines, quality control is fundamental to a company's market position. Automated Optical Inspection (AOI) technology, a key inspection method, has become indispensable for ensuring the quality of printed circuit board (PCB) assembly through its core optical imaging and advanced image processing algorithms.

For any electronics manufacturer, even the slightest flaw in any step of the SMT production line, from solder paste printing and component placement to reflow soldering, can lead to unstable product performance and even require mass rework. AOI technology, particularly inline AOI machines and pre-reflow AOI, is a powerful tool for addressing this challenge.

So, how does AOI technology safeguard your SMT production line? How does it improve product quality and production efficiency through precise inspection? Let's take a deeper look at the world of automated optical inspection.

- AOI Technology Overview: The "Sharp Eyes" of Electronics Manufacturing

1.1 What is AOI?

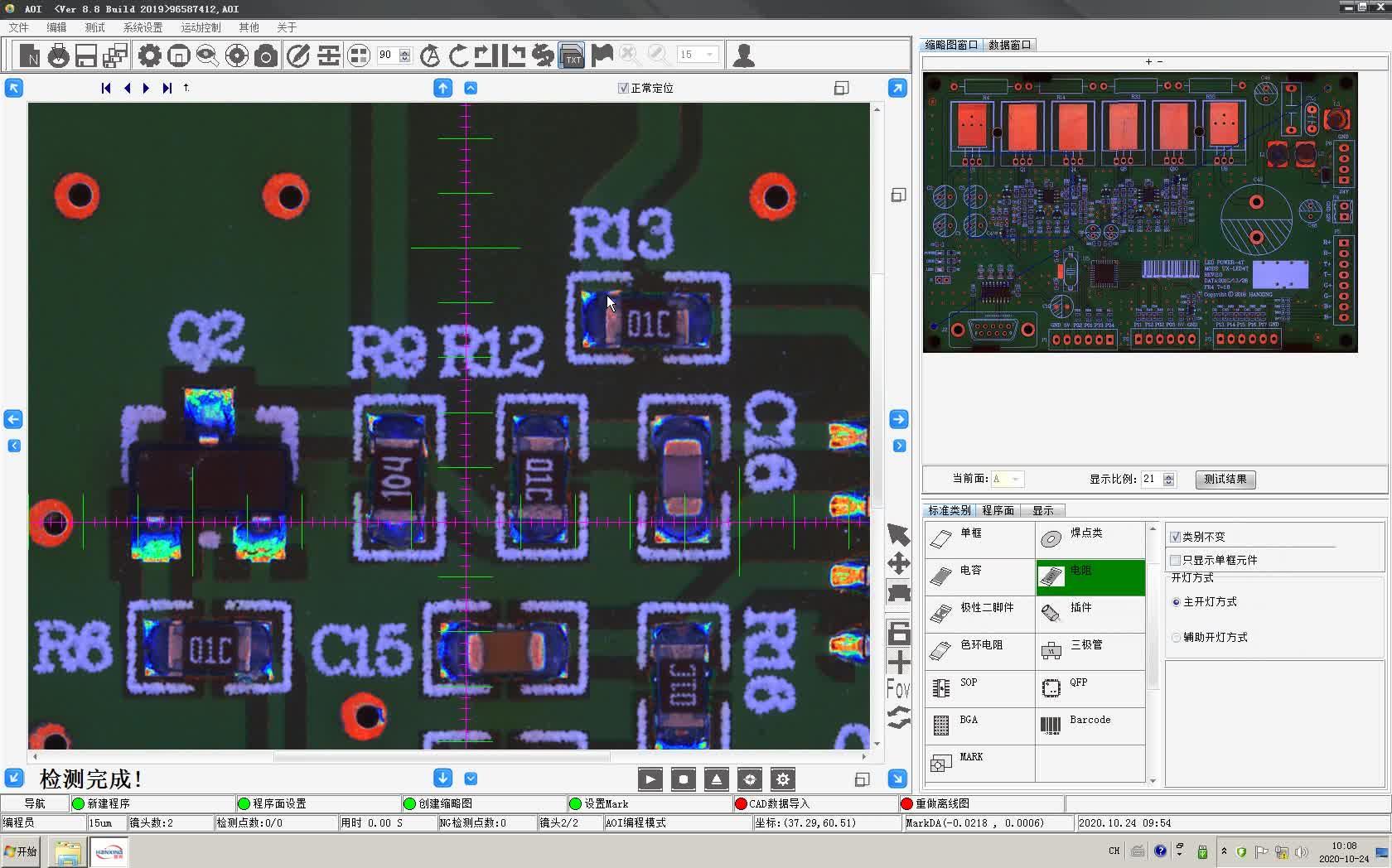

The core principle of AOI (Automated Optical Inspection) lies in the ingenious integration of optical imaging and advanced image processing algorithms to achieve high-precision inspection of electronic components and printed circuit boards (PCBs).

Compared to traditional manual visual inspection, AOI technology significantly improves defect detection rates in the electronics manufacturing process by 30%-50%. This remarkable achievement not only effectively reduces product defect rates but also significantly improves production efficiency and product quality in the electronics manufacturing industry.

1.2 The Critical Role of AOI in SMT Production Lines

In modern SMT production lines, AOI equipment acts like a tireless quality inspector, deployed at specific workstations to rigorously control the quality of every PCB.

For example, actual application data from a large consumer electronics manufacturer shows that after introducing advanced AOI equipment, the production line's first-pass yield increased significantly from 80% to 92%, and the product rework rate decreased by 35%. This not only significantly reduced production costs but also significantly shortened production cycles.

2. Inline AOI Machine: The Production Line's "Real-Time Guardian"

2.1 Working Principle and Process

Inline AOI (AOI) plays a crucial role in electronics manufacturing production lines. It is directly integrated into the production line, enabling real-time, uninterrupted automated inspection.

When a PCB moves along the assembly line and smoothly enters the AOI inspection area, the equipment's high-speed camera rapidly captures images. These images are instantly transmitted to a dedicated internal image processing unit for precise comparison with standard images stored in a database.

If the inspection algorithm identifies a defect in a product, it immediately transmits the signal to the production line control system via automated communication protocols such as Industrial Ethernet. This instant feedback mechanism enables timely correction of production process issues and reduces defective products. According to statistics, its application in automotive electronic component manufacturing has reduced production line downtime caused by solder defects by approximately 40%.

2.2 Equipment Features and Advantages

⚡ Inspection Speed

Inline AOI equipment is meticulously calibrated to perfectly match the production line's cycle time. For regular-sized, medium-complexity PCBs, the inspection speed can consistently reach 3-5 pieces per second. This speed fully meets the stringent requirements of large-scale production and effectively avoids production bottlenecks caused by inspection.

🎯 Equipment Accuracy

The optical system of the in-line AOI equipment utilizes a high-numerical-aperture lens and an advanced light source control system. Validated through extensive real-world production data, the inspection accuracy for component position deviations reaches ±0.05mm, and the detection rate for missing components exceeds 99%.

💾 Data Management

Modern in-line AOI equipment boasts powerful data management capabilities, collecting detailed inspection data in real time and transmitting it to the factory's production management system (MES). Through in-depth mining and analysis of this data, systemic process issues can be identified and guided for production optimization. For example, one company achieved a 10 percentage point increase in product yield after timely adjustments to process parameters through analysis.

3. Pre-reflow AOI: The "Quality Pre-judge" Before Reflow Oven

3.1 The Importance of Pre-reflow Inspection

Pre-reflow AOI, or AOI inspection before reflow, is an inspection process performed after component placement and before the PCB enters the reflow oven.

This step is crucial because it can detect and correct defects that occur during the placement phase, such as component offset, inversion, missing components, highlighting, and tilting, before soldering. By correcting these placement defects before soldering, complex and costly post-reflow soldering repairs can be avoided, potentially leading to scrapping of the entire circuit board.

3.2 Collaboration between Pre-reflow and Post-reflow Inspection

In SMT production lines, AOI is typically performed in two stages: pre-reflow and post-reflow.

Pre-reflow AOI focuses on inspecting component placement accuracy.

Post-reflow AOI focuses on inspecting solder joint integrity, such as excessive solder, insufficient solder, and empty solder joints. ·

The two work together to increase the surface defect interception rate to over 98%. This setup creates a solid quality defense before and after reflow.

4. Challenges and Future Trends of AOI Inspection

4.1 Limitations of AOI Technology

Although AOI technology is powerful, it is not a panacea. Its main limitations include:

Inspection Limitations: AOI is primarily capable of inspecting only the surface of an object. This makes it difficult to inspect solder joints hidden beneath or on the edges of components. For example, some connector solder bridges occur on the underside of the component, making them impossible to detect using AOI.

False Positives: AOI inspections occasionally experience false positives. For example, light can be affected by various random factors, leading to false positives. The industry generally agrees that while false positives cannot be completely eliminated, they can be reduced through various measures. Under ideal conditions, the industry generally accepts an acceptable false positive rate of less than 3000 parts per million (PPM).

4.2 Future Development Trends

With the continuous advancement of electronics manufacturing technology, AOI technology is also advancing. Future trends are primarily reflected in:

Applications of AI and Deep Learning: Deep learning is used to improve defect detection rates and reduce false positives. With the rapid development of artificial intelligence (AI) technology, particularly the widespread application of deep learning algorithms in machine vision, the accuracy and reliability of AOI inspection are expected to further improve.

The Rise of 3D AOI Technology: The 3D AOI equipment market is growing rapidly. Its application is driven by the limitations of 2D systems in detecting hidden or volumetric defects, as well as the broader trends of automation and Industry 4.0. By acquiring three-dimensional information about objects, 3D AOI can better inspect volumetric information such as solder joint height and shape.

Higher Integration and Intelligence: Integration with SMT production lines provides real-time feedback that helps optimize solder paste printing and placement processes. Meanwhile, cloud-based analytics and remote monitoring enable centralized quality control across multi-facility operations.

5. Conclusion

In today's highly competitive electronics manufacturing landscape, quality control is fundamental to a company's market presence. AOI (automated optical inspection) technology, particularly inline AOI machines and pre-reflow AOI, has become an indispensable quality guardian on SMT production lines due to its efficient and precise inspection capabilities. From improving production line efficiency to reducing rework costs and enabling data-driven intelligent production, the value AOI technology brings to electronics manufacturers is clear. With the deep integration of technologies like artificial intelligence and 3D inspection, AOI will play an even more critical role in quality control in future electronics manufacturing.

Are you already using AOI equipment? What insights can you offer on improving the quality of your SMT production lines? Contact us to share your thoughts and experiences.

Email: linda@eton-mounter.com

WhatsApp/WeChat: +86 136 7019 7725