Shenzhen ETON pick and place Machines: An Innovative Force Leading the SMT Technology Revolution

Published Time:

2025-10-14

Shenzhen ETON Automation is an innovator in SMT technology, specializing in the research, development, and manufacture of high-speed, high-precision LED placement machines. With world-leading performance and stability, it provides customers with fully automated electronic assembly solutions, effectively increasing production capacity and reducing costs. eton Automation is an industry partner in promoting "Smart Manufacturing in China."

Amidst the rapid development of the electronics manufacturing industry, Shenzhen ETON Automation Equipment Co., Ltd. is quietly transforming the electronics assembly industry with its superior chip mounter technology.

As electronic products pursue miniaturization and intelligence, surface mount technology (SMT), as a core process in the electronics assembly industry, has become an indispensable cornerstone of modern electronics manufacturing.

As an innovator in this field, Shenzhen ETON Automation Equipment Co., Ltd., with its technologically advanced chip mounter products, not only demonstrates outstanding performance in the LED chip mounter field but also provides efficient and precise solutions for the entire electronics assembly industry, earning widespread recognition from customers worldwide.

- SMT Technology: A Revolution in the Electronics Assembly Industry

SMT, short for surface mount technology, is the most popular technology and process in the electronics assembly industry. It involves mounting leadless or short-lead surface mount components (SMC/SMD, also known as chip components in Chinese) on the surface of a printed circuit board (PCB) or other substrate, soldering them together through methods such as reflow or dip soldering.

Comparison of SMT with Traditional Technologies

Compared to traditional through-hole technology (THT), SMT offers significant technical advantages:

High assembly density: The volume and weight of surface mount components are approximately one-tenth that of traditional through-hole components.

Small and lightweight electronic products: Using SMT can reduce the size of electronic products by 40%-60% and their weight by 60%-80%.

Excellent high-frequency characteristics: Reduces electromagnetic and radio frequency interference.

Easy to automate: Improves production efficiency and reduces costs by 30%-50%.

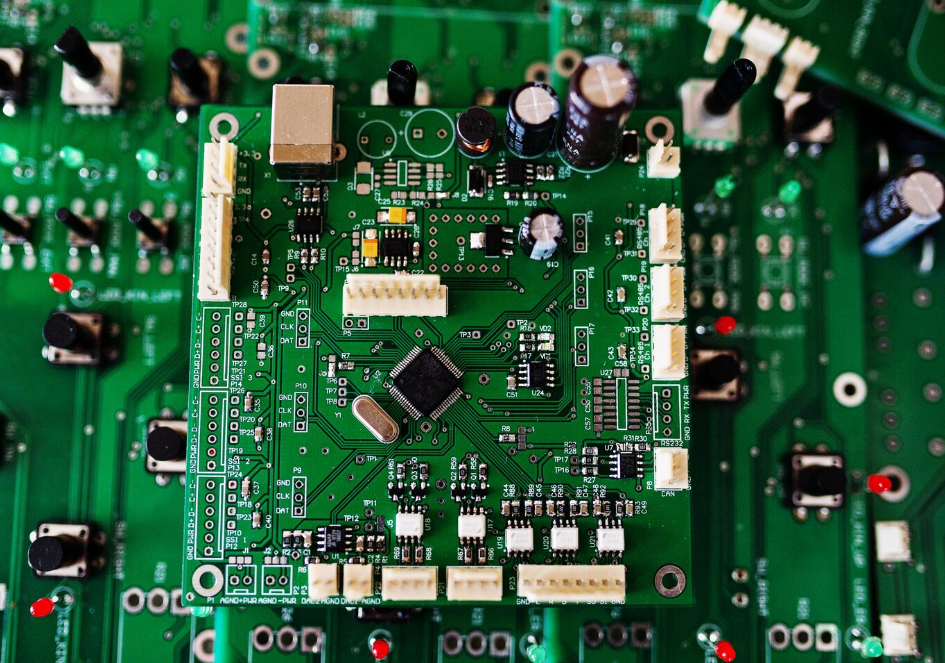

2. PCB Circuit Boards: The Solid Foundation of SMT Technology

PCB (Printed Circuit Board) is a crucial electronic component that supports electronic components and provides electrical connections for them.

In SMT technology, PCBs play a key role in carrying electronic components and providing electrical connections, serving as the "skeleton" and "neural network" of modern electronic devices.

Printed boards used for mounting and soldering surface mount components are called surface mount printed boards (SMBs). They have significantly higher requirements for heat resistance, solderability, insulation, peel strength, flatness/warpage, manufacturing accuracy, and process adaptability than fully inserted printed boards.

3. Shenzhen ETON pick and place Machines: A Leader in Technological Innovation

Shenzhen ETON Automation Equipment Co., Ltd. specializes in the research and development and production of high-speed LED chip mounters, LED display chip mounters, multi-function chip mounters, and fully automatic chip mounters. Its production capacity and stability are among the highest in the world. In response to the global trend toward green and energy-saving technologies, the rapid development of the LED industry, and the increasing demands placed on production processes, ETON, after four years of joint research with technical personnel from the United States, Taiwan, and Hong Kong, has successfully developed the ETON series of fully automatic, high-speed, energy-saving LED placement machines, which rank among the world's fastest and most stable.

Core Technical Advantages of ETON's Chip Mounting Machines

With its unique technology, strong production capacity, and comprehensive after-sales service, ETON's placement machines have revolutionized the LED placement machine industry, resolving challenges such as low production capacity and high labor costs associated with long light panels and strips. The machines have also received numerous national patents and support.

ETON prides itself on its speed and stability. ETON's unique manufacturing solutions, rigorous quality management, and comprehensive after-sales service enable us to configure professional production lines and provide technical support to our customers.

These advantages and services have enabled the company to rapidly develop into a leading global manufacturer of LED placement machines with strong R&D and manufacturing capabilities and influence.

4. Detailed Explanation of the SMT Process

SMT processing is a complex and precise process. Its basic elements include: screen printing (or dispensing), placement (curing), reflow soldering, cleaning, inspection, and rework.

Solder Paste Printing

This is the first step in the SMT production line. Its function is to apply solder paste or adhesive to the PCB pads, preparing for component soldering. The equipment used is a screen printer, located at the front end of the SMT production line. The quality of this step directly affects the effectiveness of subsequent processes and the reliability of the final product.

Component Placement

This is the core step of the entire SMT process. Its function is to accurately place surface mount components in fixed positions on the PCB. The equipment used is a placement machine, located after the screen printer in the SMT production line.

Shenzhen eton's placement machines excel in this step, enabling high-speed and high-precision component placement, ensuring that each component is precisely placed in the preset position.

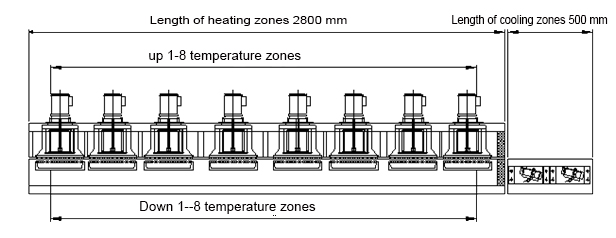

Reflow Soldering

Reflow soldering melts solder paste to securely bond surface mount components to the PCB. The equipment used is a reflow oven, located behind the placement machine in the SMT production line.

This process requires precise temperature control to ensure the solder paste fully melts and forms reliable solder joints, while also preventing damage to electronic components due to overheating.

Inspection Processes

Inspection processes on the SMT production line include a variety of advanced technologies, such as SPI (solder paste inspection), AOI (automated optical inspection), and X-ray inspection.

These inspection methods enable timely detection of defects at various stages of production, ensuring product quality. For example, AOI can detect defects such as missing parts, skew, tombstoning, misplaced parts, polarity reversal, lifted leads, solder bridges, insufficient soldering, and false soldering.

5. The Application Value of eton pick and place machines

Shenzhen eton's placement machines have performed exceptionally well in the LED industry, solving challenges such as low production capacity and high labor costs for long light panels and strips. The HT-T9, T9-2S, and HT-F9 models in the ETON HT and YT series of LED chip placement machines are among the most productive in the world. They are fully automated, high-speed LED chip placement machines that combine speed, stability, and comprehensive functionality.

Improving Production Efficiency

The high speed and precision of ETON pick and place machines enable electronics manufacturers to significantly improve production efficiency and shorten time-to-market.

In the highly competitive electronics industry, production speed is often a key factor in winning orders.

Ensuring Product Quality

Through high-precision placement and stable performance, ETON pick and place machines ensure product consistency and reliability.

In the age of microelectronics, even minor placement deviations can cause the entire product to fail, making placement accuracy crucial to product quality.

Reducing Production Costs

The automation and high efficiency of ETON chip placement machines help companies reduce labor costs and improve resource utilization.

By reducing defect rates and improving production efficiency, companies can significantly reduce overall production costs while ensuring product quality.

6. Future Development Trends of SMT Technology

As electronic products continue to evolve toward miniaturization and intelligence, SMT technology will also continue to advance. Future SMT technology is likely to exhibit the following development trends:

Higher Precision: As component size continues to shrink, the requirements for placement accuracy will become increasingly stringent.

Higher Speed: Production efficiency will become a core competitive advantage for companies, increasing the demand for high-speed placement equipment.

More Flexible Production Lines: Flexible manufacturing systems capable of adapting to high-mix, small-batch production.

Smarter Inspection Systems: The application of artificial intelligence technology in defect detection will become more widespread.

Environmentally Friendly: Environmentally friendly materials and processes will receive greater attention, in line with global sustainable development trends.

7. Conclusion

Shenzhen ETON SMT machines represent China's innovative capabilities and technological strength in the field of electronic manufacturing equipment. Through continuous technological research and development and market expansion, ETON has established a strong brand image in the global SMT equipment market, becoming a preferred partner for many electronics manufacturers.

In today's rapidly evolving electronics industry, SMT technology, as a core process in electronic assembly, will continue to drive the development of smaller, smarter, and more reliable electronic products. Shenzhen ETON, with its innovative placement machine technology and solutions, will surely play an important role in this process and make positive contributions to the development of the global electronics manufacturing industry.

In today's ubiquitous world of electronic products, SMT technology, as a core component of electronics manufacturing, is of paramount importance. Shenzhen ETON, through continuous innovation and optimization of placement machine technology, has not only driven industry progress but also provided reliable and efficient solutions to global electronics manufacturers, truly realizing the transformation from "Smart Manufacturing in China" to "Created in China."

Are you interested in it? Welcome to contact with us.

Email: linda@eton-mounter.com

WhatsApp/WeChat: +86 136 7019 7725