Chinese smart manufacturing shines in America: Eton high-precision placement machine wins praise from LEDVANCE Mexico

Published Time:

2025-09-22

Eton's YT20S pick-and-place machine, lauded by LEDVANCE in Mexico, boosted yield to 99.5%+ with its maglev and smart vision tech. It showcases China's smart manufacturing going global with high performance and reliability.

Combining superior performance with top-tier service, Eton Equipment has become a reliable partner for global optoelectronics giants.

Amidst profound changes in the global manufacturing landscape, China's high-end equipment manufacturing is rapidly expanding onto the global stage. In September 2025, Shenzhen Eton Automation Equipment Co., Ltd. celebrated a milestone: its flagship model, the Honor Series YT20S high-speed, all-in-one placement machine, successfully completed multiple rounds of rigorous evaluation and delivery to the Mexican factory of LEDVANCE, a leading global lighting and optoelectronics solutions provider, and has officially entered mass production for its high-end optical product line. This partnership not only marks Eton Equipment's official entry into the high-end market in the Americas, but also has earned high praise and acclaim from customers for its exceptional equipment reliability and exceptional after-sales service, establishing it as a new model for China's intelligent manufacturing going global.

Overcoming Pain Points: The YT20S Empowers Optoelectronics Manufacturing with Precision Placement

As a global leader in optical lighting, LEDVANCE has stringent requirements for the accuracy, efficiency, and reliability of its production line equipment. Its Mexican factory primarily produces next-generation smart lighting modules and high-end optical sensors, products that place extremely stringent demands on placement accuracy. For a long time, the factory was plagued by issues such as insufficient precision and yield fluctuations in traditional placement equipment when handling miniature and irregularly shaped lenses and sensitive optoelectronic components.

"We used to face yield losses due to insufficient placement accuracy every day," recalled Mr. Carlos Rodríguez, Production Director at the LEDVANCE Mexico factory. "The limitations of traditional equipment were particularly evident when handling miniature optical lenses and sensitive optoelectronic components. This not only impacted production efficiency but also posed challenges to product quality consistency."

Eton Automation Technology, leveraging its expertise gained over a decade of industry experience, provides customized placement machine solutions equipped with high-resolution vision positioning systems and micro-force-controlled precision nozzles. After in-depth on-site production research and technical exchanges, Eton's engineering team accurately identified the key pain points in the customer's production process and tailored a complete solution based on the YT20S equipment.

The YT20S's three core advantages solve industry challenges.

1. High-speed, high-precision, integrated design: Redefining the standard for placement accuracy.

The YT20S combines the advantages of high-speed and versatile machines, utilizing innovative, patented integrated placement head technology. This technology utilizes a lightweight, monolithic design and 10 modular, magnetically levitated, independently controlled Z-axes, achieving industry-leading placement accuracy of 0201 levels (±25μm @ 3σ). In actual operation, the equipment achieves placement speeds of up to 98,000 cycles per hour (CPH) under optimal conditions, increasing productivity by over 25% compared to customers' existing traditional models.

The use of magnetic levitation technology is a major highlight of the YT20S. Unlike traditional mechanical transmission methods, magnetic levitation drive achieves contactless and frictionless motion, significantly increasing speed while significantly reducing maintenance and energy consumption. Each placement head is equipped with an independent closed-loop control system, ensuring extremely high positioning accuracy even at high speeds. 2. Intelligent Vision and Sensing System: Empowering the Equipment with "Sharp Eyes"

The YT20S's high-speed flying recognition camera and dual-mark camera recognition system form the equipment's "vision center." The system supports three-color illumination (red, green, and blue) and blue light scanning, accurately identifying components up to 40×40mm, including challenging components like odd-shaped lenses. Leveraging advanced image processing algorithms, the system can perform identification and positioning calculations while components are in flight, significantly improving placement efficiency.

The independent vacuum sensing nozzle system ensures stable and reliable material handling. Each nozzle is equipped with a high-precision vacuum sensor that monitors the material handling status in real time. If any abnormality is detected, the system immediately activates an automatic compensation mechanism to ensure continuous production. This system is particularly suitable for handling components with extremely high surface quality requirements, such as optical lenses, effectively avoiding component damage caused by unstable material handling associated with traditional equipment. 3. Flexible Production Support: Adapting to Diverse Production Needs

The YT20S supports dual-track, dual-arm synchronous operation and can process PCBs ranging from 50×50mm to 500×450mm, providing customers with tremendous production flexibility. This feature is particularly suitable for manufacturers like LEDVANCE who frequently switch between product models, enabling them to flexibly adapt to high-mix, small-batch production needs.

In terms of energy consumption, the YT20S requires only a single-phase 220V power supply (maximum power of 1.5kW), saving over 30% compared to similar equipment, significantly reducing customers' operating costs. The equipment is also equipped with an intelligent energy management system that automatically adjusts power output based on actual production load, further improving energy efficiency.

The equipment achieves micron-level repeatability, enabling "soft landing" and damage-free placement of delicate components such as mirrors and filters, significantly improving customers' first-pass yield (FPY) and production efficiency. After actual production verification, the YT20S helped the LEDVANCE Mexico factory increase the lens assembly yield rate from the original 92% to over 99.5%, perfectly solving the production pain points that had long plagued customers.

Crossing the Ocean: Full-Life Service Earns International Reputation

The delivery of the equipment was just the beginning of the collaboration. The Ledvance Mexico factory team was particularly impressed by the "full-life, one-stop" international service provided by Eton.

During the equipment installation and commissioning phase, Eton dispatched a team of experienced engineers to Mexico. These team members not only possessed extensive experience in equipment commissioning but also received professional cross-cultural communication training, enabling them to effectively overcome time zone differences and language barriers and conduct efficient on-site installation and technical training. Within two weeks, the engineering team completed the equipment installation, commissioning, and optimization, ensuring that the Mexican engineers quickly mastered equipment operation and routine maintenance skills.

In addition, Eton's 24/7 online technical support system provided immediate response across the Pacific. Any technical questions could be diagnosed and resolved remotely, as if a "cloud engineer" was always available at the customer's side. The system supports multiple languages, ensuring accurate and efficient communication.

During the project implementation, Eton's engineering team demonstrated exceptional professionalism. To meet the unique requirements of optoelectronic product production, the team precisely completed the high-precision positioning and leveling of the YT20S chip mounter, ensuring micron-level placement accuracy. Notably, the engineering team also proactively assisted the client in positioning and installing the entire line equipment, including the upper and lower docking stations and reflow ovens, demonstrating a comprehensive service philosophy.

"The Eton team's professionalism is impressive," said Carlos Rodríguez, Production Director at the Ludvance Mexico plant. "They not only quickly resolved technical issues such as the transport and displacement of the vibrating plate, but also helped us optimize the overall equipment layout. This comprehensive technical support significantly shortened our production cycle."

During the project, the team encountered unexpected events such as torrential rain that flooded the workshop. Eton engineers worked closely with the client team, working overtime to meet deadlines and ultimately ensure the overall project progress. "Natural disasters are unavoidable, but we can minimize their impact through professionalism and dedication," said the on-site engineer. "Our customers' understanding and support are our greatest motivation."

Customer Praise: Dual Benchmarks in Technology and Service

Mr. Carlos Rodríguez, Production Director at the Ledvance Mexico plant, spoke highly of this collaboration:

"We evaluated placement equipment from multiple countries, and the Eton placement machine was a pleasant surprise. Its exceptional precision and stability fully met and even exceeded our expectations for high-end optical product manufacturing, significantly improving our yield rate. Even more remarkable, the Eton team's professionalism, responsiveness, and sincere problem-solving attitude made us feel this was a truly reliable partnership."

"The YT20S's precision and stability completely exceeded our expectations for domestic equipment. Its integrated magnetic levitation placement head and intelligent vision system perfectly resolved our previous yield issues in lens placement. Even more remarkable, the Eton team's service responsiveness and professionalism rival those of top international brands. They are not just a supplier, but a strategic partner in improving our manufacturing processes."

The Eton YT20S placement machine performed exceptionally well in this project. Its high-speed flying recognition camera and dual-mark camera recognition system perfectly addressed the placement challenges of micro-lenses and sensitive optoelectronic components. The equipment supports dual-track, dual-arm synchronous operation and can flexibly adapt to the production needs of multiple varieties, providing Ledvance with an efficient and stable production solution.

A Global Breakthrough for Domestic Chip Mounters

The successful overseas launch of the YT20S demonstrates the global competitiveness of China's high-end equipment. Eton Automation holds over 200 patents (including 25 invention patents), and the YT20S boasts over 95% self-developed technology, achieving independent control over everything from underlying algorithms and optical systems to precision motors. This deep technological independence not only ensures product reliability but also lays a solid foundation for future technical upgrades and service support.

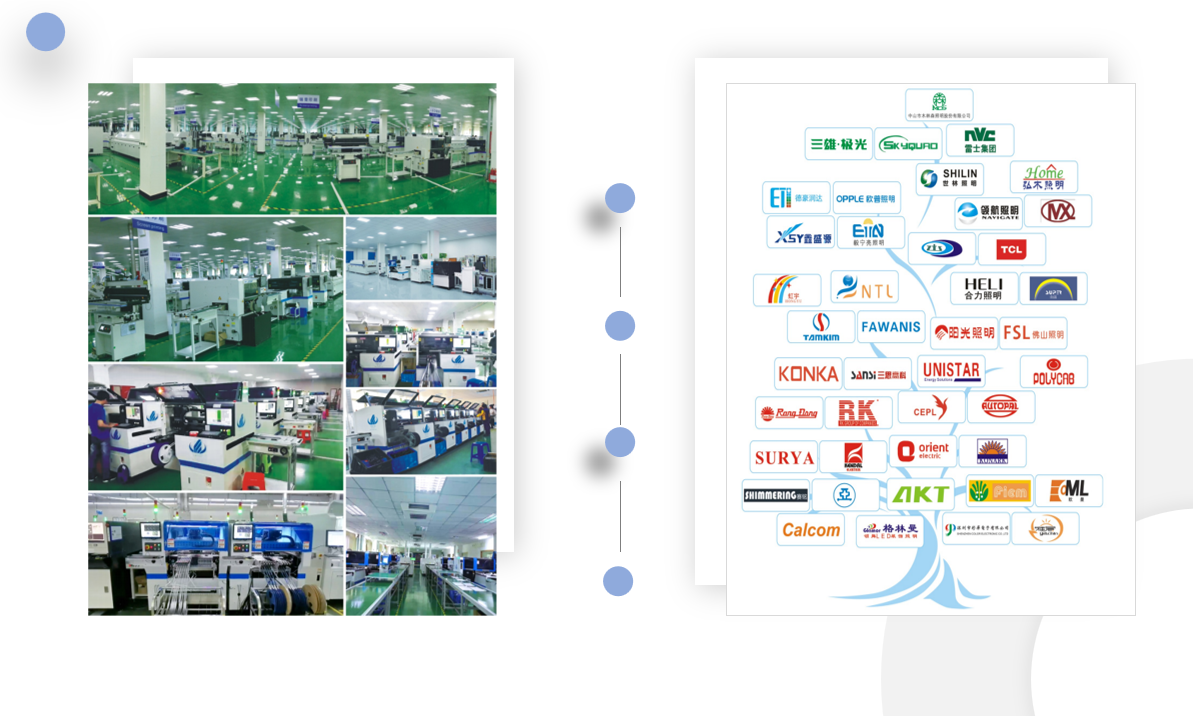

Currently, Eton equipment has been exported to over 40 countries and regions worldwide, including developed manufacturing nations such as South Korea, Spain, and Brazil, with technical performance comparable to that of international brands. In numerous international projects, the YT20S has competed against equipment from renowned international brands, demonstrating excellent cost-effectiveness and service advantages.

Yu Yaoguo, founder of Eton Automation Technology Co., Ltd., stated: "We firmly believe that Made in China must not only offer competitive prices but also achieve world-class technology and service. The success of the YT20S project in Mexico proves that we are on the right track. We will continue to deepen our core technologies to make domestic chip mounters an indispensable force in the global industrial chain."

A New Chapter in China's Intelligent Manufacturing

This collaboration not only brought a leap in production efficiency to Ledvance, but also set a new benchmark for Chinese intelligent manufacturing in the global high-end equipment market. Currently, the entire production line has completed mechanical positioning and horizontal commissioning and entered the trial production phase. The successful implementation of this project provides valuable experience for Chinese intelligent manufacturing equipment to enter the Latin American market.

The General Manager of Eton Automation Technology stated, "The success of the Mexico project is just the beginning. We will continue to deepen the development of our international service system and provide even higher-quality products and services to global customers. The experience gained from this project will provide important reference for further expansion into the Americas market. We plan to establish a technical support center in Brazil next year to better serve the South American market."

The successful export of Eton equipment to Mexico and its recognition by international giants is another powerful example of China's high-end intelligent manufacturing equipment entering the global market with its superior quality and high-quality service. This not only brings commercial success, but also earns a resounding reputation for "Made in China" in the international market, demonstrating the Chinese manufacturing industry's resolute progress in transforming from "manufacturing" to "intelligent manufacturing."

About Eton Automation Technology

Established in 2011, Eton Automation Technology Co., Ltd. is a National High-Tech Enterprise and a Guangdong Province Specialized and Innovative Enterprise. The company specializes in the research, development, and manufacturing of high-end SMT placement machines. Its products are renowned for their high precision, high speed, and high stability, and are widely used in communications, optics, automotive electronics, artificial intelligence, and other fields. The company holds over 200 patents, including 25 invention patents, ranking first among domestic SMT placement machine manufacturers. With customers in over 40 countries and regions, the company enjoys a strong international reputation.

About LEDVANCE

LEDVANCE is a leading global provider of lighting products and solutions. Formerly part of OSRAM's general lighting business, it boasts a rich brand history and technological heritage. Its products cover a wide range of sectors, including professional lighting, smart home lighting, and OLED lighting, with a global presence in over 120 countries and regions. LEDVANCE is committed to improving people's quality of life through innovative lighting technology and maintains a leading global position in optical lighting.

Are you interested in it? Welcome to contact with us.

Email: linda@eton-mounter.com

WhatsApp/WeChat: +86 136 7019 7725